Features

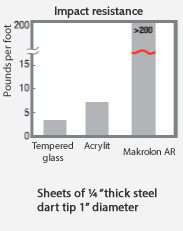

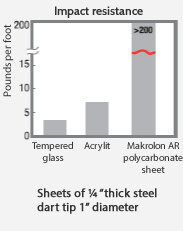

- Extreme high impact resistance

- Lightweight: 50% lighter than glass

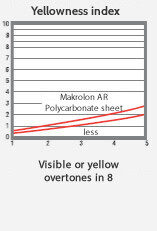

- High light transmission

- Self-extinguishing

Benefits

- Freedom in design

- Savings on installation costs and electricity

- Contributes to obtain Leed credits

- Energy savings thanks to its high light transmission and insulation

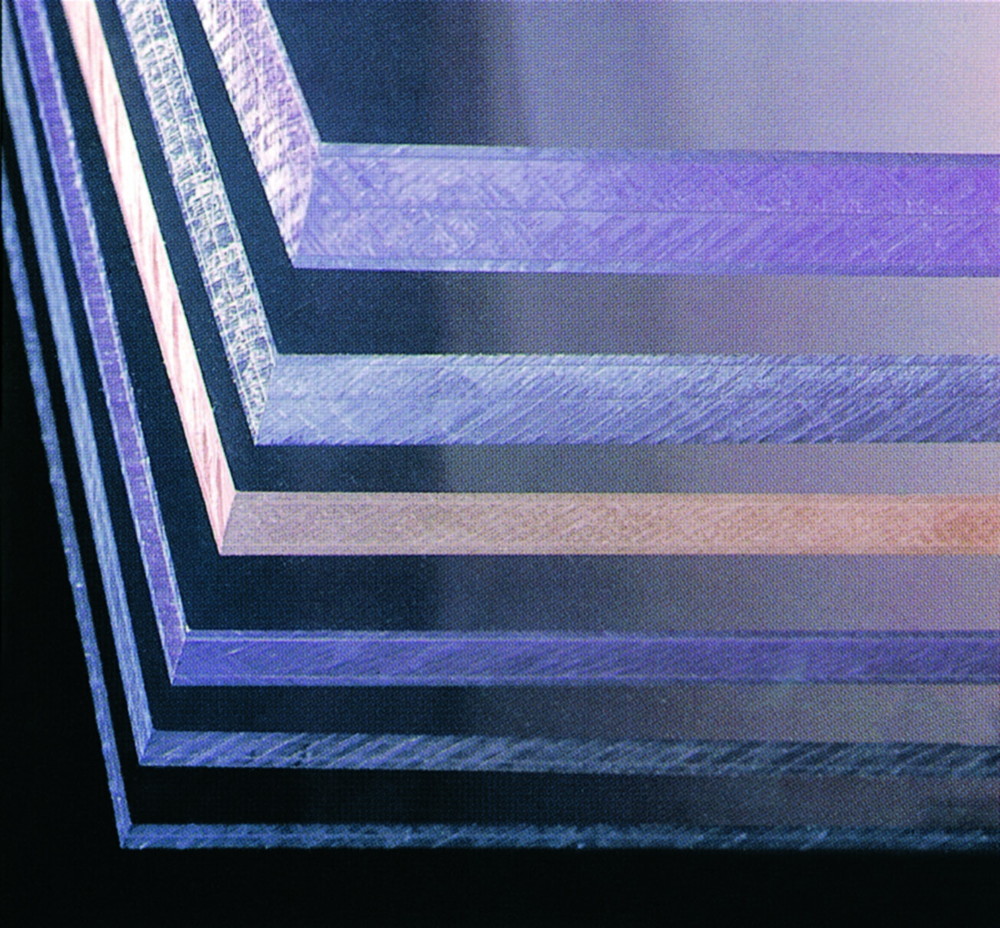

Mono GP

This is the simplest solid polycarbonate product from our product range. Ideal for any type of application where extreme impact resistance is a must but the UV Protection is not fundamental.

Mono SL

Our Mono SL Polycarbonate offers the same impact resistance as Mono GP with additional one sided UV protection, resulting long lasting product which protects the inside areas against the harmful rays.

Mono AR

Offers double sided UV protection with additional finish against common scratches in one or both sides.

Mono AB (Anti Ballistic)

Mono AB is employed wherever special protection is required for persons and/or objects. These include high-level security areas such as banks, jeweler’s shops, prisons,court buildings or night desks. Other fields are possible targets for vandalism, e.g. museums or buildings with large glazed sections. Mono AB offer clear economic and functional advantages over bullet-proof glass.

| Common uses of Polycarbonate solid sheets: | |||||||

|---|---|---|---|---|---|---|---|

| Macrolux | GP | SL | AL | Macrolux | GP | SL | AR |

| Architectural roofing |

|

|

Division and cancel |

|

|

|

|

| Industrial roofing |

|

|

Domes |

|

|||

| Roofing pools |

|

|

Graphics Arts |

|

|||

| Arcs canyon |

|

Industrial parts |

|

|

|

||

| Windows |

|

|

|

Protection artworks |

|

||

Technical Specification of Solid Polycarbonate Sheets

The solid polycarbonate panels satisfy the most important construction codes like:

- CC-1* Category for construction applications (BOCA, ICBO, SBCCI)

- Underwriters’ laboratory flammability standards (UL 94 and UL 972) for glazing materials.

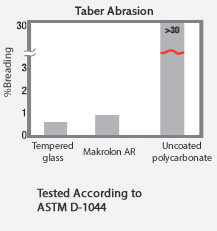

Macrolux AR

Macrolux Mono AR, GP, SL

| Chemical Resistance / ASTM D-1308 | |

|---|---|

| Chemical | Resistance Time |

| Acetone | > 24 Hours |

| Ethylene dichloride | > 24 Hours |

| Unleaded petrol | > 24 Hours |

| Hydrochloric acid (10%) | > 24 Hours |

| Methyl alcohol | > 24 Hours |

| Methylene chloride | > 24 Hours |

| Ketone, methyl alcohol | > 24 Hours |

| Nitric acid (100%) | > 24 Hours |

| Sodium hydroxide (19%) | > 24 Hours |

| Sulfuric acid (1%) | > 24 Hours |

| Toluene | > 24 Hours |

| Isopropanol | > 24 Hours |

| Kerosene | > 24 Hours |

THERMOFORMING

To thermoform Macrolux Solid sheet is important pre-dry in a dehumidifier oven (circulatory air). The pre-drying time depends on the thickness of the sheet.

| Drying Time | ||

|---|---|---|

| Sheet thickness | Maximum temperature of 121 ° C | Maximum temperature of 82.2ºC |

| 2.00 mm | 2 Hours | 4 Hours |

| 3.00 mm | 6 Hours | 14 Hours |

| 4.50 mm | 12 Hours | 30 Hours |

| 6.00 mm | 24 Hours | 50 Hours |

Cold bending

Macrolux Mono GP and SL polycarbonate sheets can be bent cold until a minimum curve radius depending on its thickness. As a rule, the radius of curvature should be equivalent to 100 times the material thickness. R = TX100

R = TX100

| Sheet bending based on thickness | |

|---|---|

| Sheet thickness (T) | Minimum bend radius (R) |

| 2.00 mm | 20 cms |

| 3.00 mm | 30 cms |

| 4.50 mm | 45 cms |

| 6.00 mm | 60 cms |

| 9.50 mm | 95 cms |

| 12.70 mm | 127 cms |